David E. Johnson

Types of Tumblers

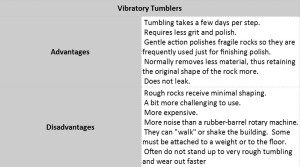

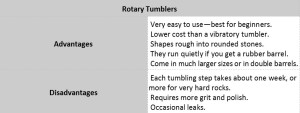

Two types of tumblers are used by most hobbyists: 1) rotary rock tumblers; and 2) vibratory rock tumblers. Each of these tumblers have advantages and disadvantages. If you want to buy a rock tumbler or a rock tumbler kit, the best thing that you can do is learn about each of them and make an informed decision. There are also inexpensive tumblers made to introduce children to the hobby. These kids’ tumblers have plastic barrels and they make a LOT of noise and will wear out very quickly; but they have a low price.

For beginners I recommend a hobbyist-quality rotary tumbler with a metal frame and a soft rubber barrel. They cost a bit more but they run quietly and will last for years.

In summary, rotary rock tumblers are the most popular. They have the ability to transform angular rock fragments into rounded rock fragments in five to six weeks. In contrast, vibratory tumblers do little to alter the shape of the rock, instead they are more efficient at smoothing the surfaces of the rock quickly—they require about one to two weeks to process a batch of rock.

Rotary rock tumblers are typically less expensive than vibratory tumblers. Expect to spend at least $80 for a small rotary tumbler with a rubber barrel or about $200 for a small vibratory tumbler.

The best of both worlds is to process the rocks in a rotary tumbler for the coarse grind to achieve a rounded shape. Then use the vibratory tumbler to quickly do the fine grind, pre-polish and polishing steps.

When choosing a tumbler, the primary consideration is what size stones you want to tumble. About half the diameter of the barrel is as large as you can finish. Therefore, your least expensive models with a barrel four inches in diameter can only finish two-inch diameter stones. Moving up to a machine twice that size will cost twice as much, require twice the abrasives, and use twice the amount of filler. For the serious lapidary this is reasonable, but for the part time hobbyist it may not be justifiable.

When considering your budget, include an extra barrel for your machine. Reserve it for polishing only. This is especially important if you are using a rubber barrel. They are very difficult to get completely clean. If you have any abrasive, even one or two little pieces, left in the barrel when you try to polish, it will scratch your stones.

Rotary Rock Tumblers

A rotary tumbler has one or more barrels that the rocks are placed in. Multiple barrels allow you to tumble two or more batches of rock at the same time. You can tumble two different types of rock or you can tumble two batches of rock at different stages of the tumbling process. The barrels are turned by a motor and the rocks tumble inside of the barrel, rubbing against one another and wearing their way smooth.  A number of companies manufacture rotary tumbling machines. They are the most commonly used type of tumbler. Rotary rock tumblers are made by companies like Lortone, Inc. and Thumler’s Tumblers.

A number of companies manufacture rotary tumbling machines. They are the most commonly used type of tumbler. Rotary rock tumblers are made by companies like Lortone, Inc. and Thumler’s Tumblers.

The tumblers shown are made with metal frames, have durable rubber barrels and will tumble two or more pounds of rock at a time. They are designed to give years of reliable service if they are cared for properly.

Plastic tumbling machines for children are also sold. These plastic tumblers cost less and are designed to tumble a small handful of rocks at a time. These plastic-barrel tumblers make a LOT of noise and will last for just a few batches of rock if you are careful and do not overload them.

Vibratory Rock Tumblers

Vibratory tumblers have a bowl instead of a barrel, which uses ultrasound or spins around a vertical axis. Rocks, grit and water are loaded into the bowl, covered, then allowed to vibrate. This vibrating action causes friction between the rocks and grit and results in rocks with smooth surfaces. The action in a vibratory tumbler does little to round the shape of the rocks. Vibratory tumblers can process a load of rocks in about 50% of the time required by a rotary tumbler. Vibratory tumblers are made by companies like Johnson Brothers and Thumler’s Tumblers.

Which One Should You Buy?

Which One Should You Buy?

The type of tumbler that you should buy depends upon the types of material that you will be tumbling, how fast you need results and how much rock you have to tumble. Here are some of the advantages and disadvantages of each. In summary, if you are starting out with crushed rocks with jagged edges and desire tumbles that are nicely smoothed and rounded then a rotary tumbler is best for you.

A vibratory tumbler does not do a lot of shaping. So if you put in angular rocks your finished product will be angular tumbles. On the other hand, if you are working with pre-shaped rocks, such as beach stones, cut cabochons and thin slabs, or very delicate material such as glass or obsidian, then a vibratory tumbler would probably be more effective.

Also, if you opt for a rotary tumbler, purchasing a double-barrel tumbler is helpful in reducing tumbling time. Two barrels allow you to simultaneously tumble rocks in two different steps of the tumbling process, or rocks of two different hardnesses.

Tumbling Supplies:

In addition to a rock tumbler you will need some rock tumbling supplies. These include: tumbling rough (rocks to tumble), tumbling grit, rock polish, tumbling media—material to cushion the rocks or fill the barrel to the proper level; like plastic pellets or ceramic pellets. All of these supplies are necessary and learning about them will improve your tumbling success and enjoyment.

Tumbling Rough

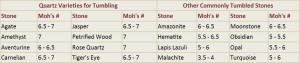

Tumbling rough is crushed or broken rock material that you hope to get polished in a tumbler. The quality of the finished stones that you produce will be mainly determined by the quality of rough rock that you place in the tumbler. Most rock will not tumble to produce a highly polished gem. You must use the right types of rock. Agates, jaspers, flints and quartz minerals are the most commonly tumbled rocks. These are hard, solid materials that can be free of voids and grainy textures. Sedimentary rocks such as sandstone, siltstone, shale, limestone and coal, or metamorphic rocks like schist, slate and gneiss will normally just break up or not polish at all. Most igneous rocks contain several different minerals that wear down at very different rates and won’t tumble uniformly. Do research, experiment or ask an experienced person if you are uncertain about your rocks.

Many people live or travel where good tumbling rough can be collected. If you are one of those people you are very fortunate! Most people live where good tumbling rough is hard or impossible to find so they purchase most of their tumbling rough. It’s great to collect your own rough but there is nothing wrong with purchasing it! Even people who can collect their own should buy a little exotic material to bring a little adventure to their hobby. There are many rock shops and internet sites where you can purchase wonderful, colorful varieties of rock that you would probably never find in a lifetime of fieldwork. Any rock with a Moh’s hardness of 5 to 7 will generally polish well in a tumbler; agates and jaspers are very suitable and come in many colors and patterns. Generally, if the rock rough has a glassy luster, it will tumble to a shine well; if it has an earthy luster it will likely have an earthy luster after tumbling. Here are some commonly tumbled stones:

Tumbling Grit

Tumbling grit is an abrasive sand or powder—usually made of silicon carbide. It is placed in the tumbling machine with rough rock. The grit is much harder than the rocks that you tumble. As the rocks move in the tumbler the grit gets caught between them and wears them away. This is an abrasive action similar to sand paper.

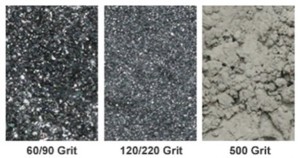

Tumbling grit comes in different sizes such as 60/90 (coarse), 120/200 (medium) and 400/600 (fine). Coarse grit is a sand-size material and is the most abrasive. It is used in the first step of the tumbling process to round the sharp edges off of the rough. Medium grit is the size of fine sand. It is used to smooth the surface of the rounded rocks. Fine grit is a powder-size material that is used as a prepolish. It removes scratches left by the medium grit and prepares rock surfaces for polishing. As silicon carbide breaks down it continuously breaks to another sharp edge. Coarse won’t stay coarse, but it breaks down to medium and then to fine and to finer, so it is always working and it never rounds. As it gets smaller it loses its effectiveness to really shape rough rock but still grinds. If it can be located, sometimes 46/70 extra-coarse grit is used as an extra step to remove the crust off of a rock.

Rock Pre-Polish and Polish

Rock polish is an abrasive powder that buffs the smooth surfaces of prepared rock to a high polish. It is what produces the shiny luster on the surface of finished tumbled stones. Several different compounds are used as a rock polish. These include: aluminum oxide, tin oxide, cerium oxide, tripoli and others. These are used as the final step of the rock tumbling process.

Sometimes a 500 grit silicon dioxide or a 500 grit aluminum oxide are referred to as a pre-polish. This step removes all scratches left by the 120/220 grit and prepares the surface of the rocks for the polishing step.

Tumbling Media

Rocks tumbling in a barrel from several days to a week take a lot of pounding and abuse. The repeated impacts can cause some of the rocks to chip, bruise or crack. This is especially tr ue if a batch of large rocks is being tumbled with no small rocks between them to buffer their actions. To protect the rocks—especially in the fine grind and polishing steps—plastic pellets or ceramic beads are often added to the tumbling barrel. The soft plastic beads can provide cushion from the impacts and the ceramic beads can fill the spaces between the large rocks and provide support.

ue if a batch of large rocks is being tumbled with no small rocks between them to buffer their actions. To protect the rocks—especially in the fine grind and polishing steps—plastic pellets or ceramic beads are often added to the tumbling barrel. The soft plastic beads can provide cushion from the impacts and the ceramic beads can fill the spaces between the large rocks and provide support.

Final Polishing Examples and Suggestions:

Adventurine— Tin oxide on leather.

Agate— Cerium oxide on canvas.

Alabaster— Tin oxide on leather.

Amazonite— Tin oxide on leather.

Amber— Tin oxide on leather.

Apatite— Linde A on leather.

Azurite— Chrome oxide on chrome tanned leather.

Beryl— Linde A.

Bloodstone— Linde A on canvas.

Chiastolite— Linde A. on leather.

Chrysoberyl— 50,00 or 100,000 diamond.

Chrysocolla— Cerium oxide on canvas.

Cinnabar— Linde A on leather.

Coral— Tin oxide on leather.

Corundum— 50,00 or 100,000 diamond.

Cubic Zirconium— 50,00 or 100,000 diamond.

Datolite— 50,00 or 100,000 diamond.

Epidote— 50,00 or 100,000 diamond.

Feldspar— 50,00 or 100,000 diamond.

Flourite— 50,00 or 100,000 diamond.

Garnet—Linde A on leather.

Glass— Cerium oxide on canvas.

Gypsum— Tin oxide on leather.

Hematite— Cerium oxide on canvas.

Hickoryite— Linde A on canvas.

Howlite— Cerium oxide on canvas.

Jade— Linde A on leather or chrome oxide on chrome tanned leather.

Jadeite— Linde A on leather.

Jasper— Cerium oxide on canvas.

Labradorite— Tin oxide on leather.

Lapis Lazuli— Tin oxide on leather or chrome oxide on chrome tanned leather.

Malachite— Tin oxide on leather.

Moonstone— Tin oxide on leather.

Obsidian— Tin oxide on leather.

Opal— Cerium oxide on canvas.

Peridot— Linde A on leather.

Rhodocrosite— Tin oxide on leather.

Rhodonite— Cerium oxide on canvas or chrome oxide on chrome tanned leather.

Ruby— Diamond on wood.

Rhyolite— Cerium oxide on canvas.

Other Handy Items:

A number of other items will be needed while tumbling. Here is a list of what I keep on hand or have easy access to while tumbling. You might not need all of them or you might add others to the list.

* Water * Paper towels * Bucket * Household oil * Colander or screen * Basin

* Old towel * Measuring tablespoon * Knife * Bar of Ivory Soap or flakes

Rock-Breaking Equipment:

* Rock hammer * Safety goggles (required for breaking rock and cleaning rocks)

* Gloves (required for breaking rock) * Heavy cloth (required for breaking rock)

Optional Items:

* Extra barrel for polish step * Extra grit, polish and pellets

* Extra tumbling rough * Small scale * Old toothbrushes